Dane Whitehurst is the creative director of packaging design company Burgopak where he’s been working in packaging for the last 17 years. Burgopak is a small business with a staff of 25 based in London.

HOW DID YOU GET INTO PACKAGING?

I’d done a degree in product design and followed that with a master’s degree in industrial design and I was very interested in designing furniture and lighting. I briefly went into teaching but was quite keen to get back into

design.

I went to visit a friend who is also in design and his housemate had just got a job as the head of design for this very interesting packaging company called Burgopak. And I said I was really looking to get back into London and into design. He said ‘we’re hiring actually, come for an interview’ and so I did, and I’ve been there ever since.

WHAT’S THE APPEAL OF PACKAGING?

I think the nice thing about packaging is that, as a designer, you’re kind of responsible for everything. You get to see a project right from the moment it comes into the studio—those first conversations with the client where you’re figuring out what they’re hoping to achieve—and you’re involved in every step.

You’re working with materials, manufacturing processes, and you really have to understand the brand inside and out. At the same time, you need to know how materials work and behave, and often, you’re figuring out how to deliver something that looks amazing but stays within a modest budget.

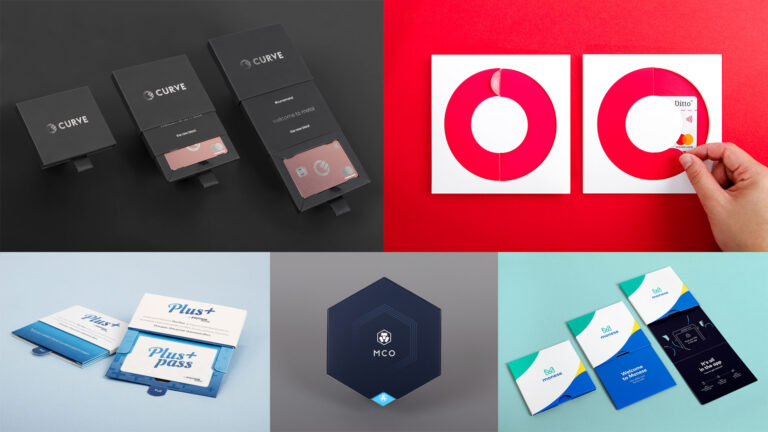

The world of packaging can seem quite dry and stale. I mean, there’s a lot of brown Amazon boxes and basic folding tuck cartons out there—things designed purely for low cost and efficiency. But that’s not the space we work in. For us, it’s about creating customer experiences through packaging that really drive brands forward.

WHEN SHOULD A PRODUCT-BASED BUSINESS CONSIDER PACKAGING?

I would say really early on for a number of reasons. Firstly, you want to get it right. So, the example which I think is very accessible is Apple.

If you don’t think your packaging is important and affects the way that the customer receives your brand and your product, imagine for a second that Apple did some really horrible packaging. For a high ticket item, do you expect low ticket packaging? The packaging itself chimes with the brand and the price point.

Another reason is that packaging is often the first touch point for a customer and the story that it tells is super important.

We actually work with a lot of banks and sending a bank card to a customer can be a physical manifestation of a ‘welcome to our business’ and ‘welcome to our relationship’. So, the value of that moment is high.

The other thing about packaging is it gives you a really interesting, limited canvas to tell your story. It forces you to cut all the rubbish and get to the core of what you offer.

Development time for a piece of packaging can be relatively long, much longer these days than people expect. This is a real physical thing that has to go through a design process, a validation process and it also needs to be printed, cut, assembled and potentially shipped somewhere geographically.

It’s not like if you launch an app or a website where the deployment date is fixed, and it’s done.

SHARE AN EXAMPLE OF A PROJECT YOU’VE REALLY ENJOYED:

There’s a really simple project that we did fairly recently, and it was for Monzo Bank around their bank card packaging.

We’ve now been working with them for a number of years but with this one, they basically asked us to see if there were any efficiencies that we could build into the packaging they had. It was already pretty efficient anyway.

Alongside this, I’d also been working quite hard on developing a Life Cycle Assessment (LCA) module. It’s basically a calculator that can highlight the carbon footprint of the raw material, the manufacturing processes, transportation and end of life. Doing this had allowed us as a company to benchmark where we are at any given moment with regards to sustainability.

We used this on this Monzo project and it was fascinating what emerged from it. We went back to the customer and said if ‘we make your pack seven millimetres smaller we will fit 20% extra on a print sheet’.

This means that in their first production run, we would save nearly 1 1/2 tonnes of paper and nearly two tonnes of carbon across the whole supply journey. This was massive for a relatively small change.

We’ve spent a lot of time working on embedding sustainability into the work that we do, and this was one of the first examples where we really actively used it to make a difference.

ANY OTHER EXAMPLES LIKE THAT?

Another really nice project we did was for Ancestry.com – the genealogy company.

When a customer signs up to Ancestry.com, they are sent a ‘kit’ to provide a sample of saliva. The company sends out a collection device which the customer uses to provide the sample and then it’s placed back into the box.

We’re producing quite high volume for them, and their existing packaging was a pizza-box style ie. a lid that opened up and we needed to try and leverage some environmental improvements.

We set about adapting it to create a telescopic opening experience – taking the mechanism and stripping it back to components that were really easy to assemble using as little material as possible.

We weighed the original packaging and then we weighed the new packaging to make sure that we were under at least by some margin.

On the original packaging we managed to remain, as far as I understand, fairly cost neutral, but we saved almost 30% in terms of the weight of the packaging.

In the end, we created something that really is a beautiful piece of design.

HOW IMPORTANT IS SUSTAINABILTY IN YOUR WORLD?

I think it’s massively important and there’s a lot of legislation coming out across Europe now and into the future.

I should say our products are almost entirely paper based. We work in cardboard and that’s our medium.

As a designer you have a responsibility to not fill the world with loads of junk. A lot of the work that we do is around making sure that we use the best materials that we possibly can.

We are working very closely with different paper mills to understand their processes and we’re FSC certified, so we make sure all the material we use comes from sustainably managed forests that are independently audited by the Forestry Stewardship Council.

We analyse everything and we have values for the different materials that we use. We understand how much of them we do use, and then we look at supply chains as well. We are driving down transportation as much as possible and trying to avoid using air freight.

I think people often keep really nice packaging, yet it is disposable at some point. It’s being able to design things that are as efficient as possible, but also can be easily recycled and disposed of as sustainably as possible. Legislation is moving in the right direction to guide the practices of the industry and that aligns with my values and the values of the company.

WHAT ARE THE TRENDS FOR PACKAGING IN 2025?

Sustainability is very important and will continue to be. I think the number one thing in all of that is to look at the material that you’re using and really understand the impact of that. Make a decision and have a position on which materials you will and won’t use.

Burgopak specialises in world class packaging and has created several innovative packaging designs which are trademarked to them and include patented technologies. Today the team put sustainability at the heart of the business.

By Feature writer Fiona Scott, Scott Media